Graphic Overlays China is a professional manufacturer of Premium Quality Custom Printed Graphic Overlays, Screen Printed Graphic Overlays, Electrical Overlays, Front Panel Overlays and Membrane Switches.

Need Graphic Overlay Prototyping?

Don’t worry! We can do Rapid Graphic Overlay Prototypes, No MOQ, Low Cost and Fast Turnaround.

Can you print Colored Graphic Overlays?

Yes! We can do Digital or Offset CMYK Full Color Printing. We can combine digital printing with traditional screen-printing to satisfy your needs.

What is a Graphic Overlay?

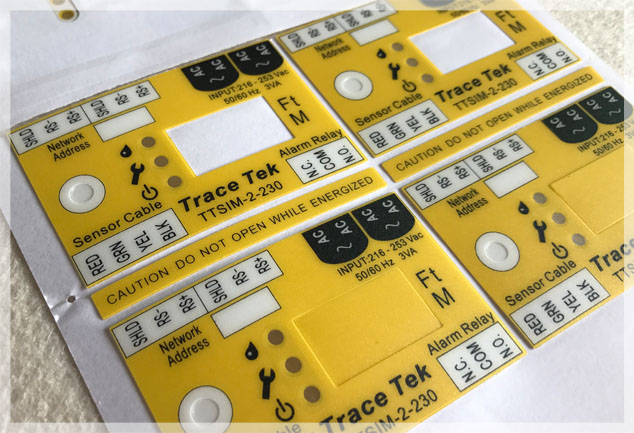

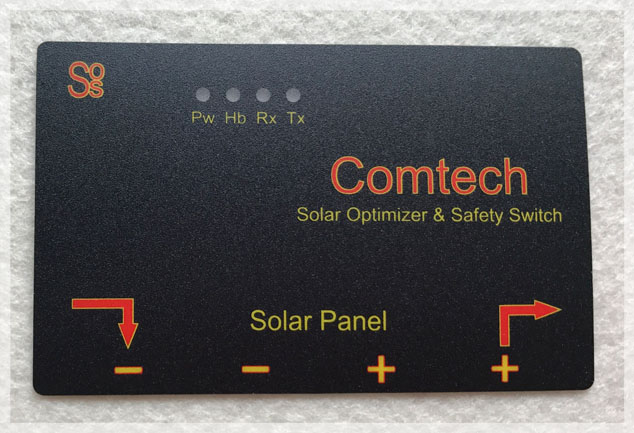

A graphic overlay, faceplates, nameplates, front panel or function user interface is a kind of silk screen printed or digital printed graphic sheet or panel that is placed on the surface of a product.

A graphic overlay provides a powerful impression of your equipment and often provides a critical high level of function.

It’s a Human-Interface panel, graphic overlay provides a high quality finish for products, communicate messages, and act as the interface between people and products.

How are Graphic Overlays produced?

Graphic Overlays are printed on the subsurface of the material like transparent polycarbonate. After printing, double sided adhesive is applied to the back. Then die cut to shape. It’s done!

Which material can be used for graphic overlays?

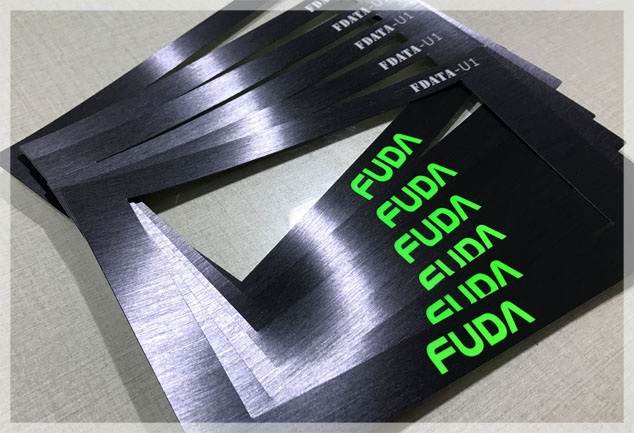

Graphic Overlays can be created from a wide variety of material such as polycarbonate, polyester, PVC, vinyl, acrylic and even metal(Anodized Aluminum). Typically, a graphic overlay is made of polycarbonate or polyester.

Polycarbonate material thickness from 125 micron to 750 micron. 125 microns, 175 microns, 250 microns, 380 microns, 500 microns and 750 microns etc. Commonly used is 250 microns thickness.

What colors and printing options are available?

We manufacture a full line of graphic overlays from single color to full color graphic overlays.

Graphic overlays are traditionally subsurface screen printed, predominantly spot color screen printed or full color digitally printed, but can be UV offset printed as well.

- Pantone Matching System

- RAL Color Matching

- Client’s Sample Color Matching

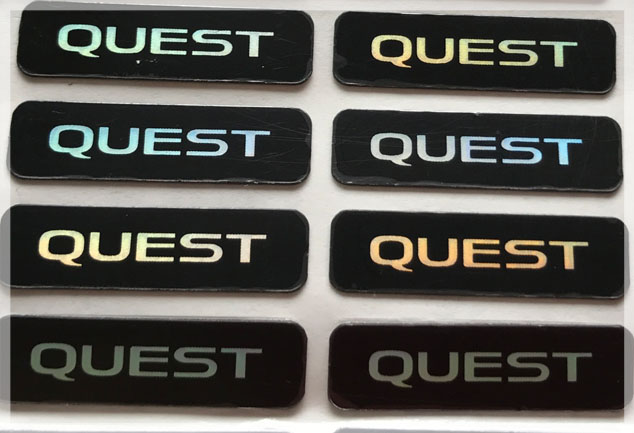

Metallic Inks: Metallic Gold Ink, Metallic Silver Ink, Mirror Silver Ink, Mirror Gold Ink, Holographic Effect, Glow in the Dark and Fluorescent Ink.

Graphic overlays are traditionally screen printed, using 4-color process, U.V. inks, Pantone® colors, or metallic inks. We can accurately match color values, densities, and gloss levels, providing exceptional product color match and production consistency.

In most cases, the graphic overlays we manufacture are done with silk screen printing. However, we have additional printing capabilities including UV digital printing, UV Offset Printing and UV Flat Pad Printing.

Screen Printed Graphic Overlays

For most of our projects, we use screen printing method. Colors are printed one at a time and can be matched to a pantone color specification (PMS) or to a customer supplied sample.

Screen printed overlay advantages like cost effective for mass production, excellent color matching capability, selective texturing of gloss materials and durable inks etc.

Digitally Printed Graphics

We offer our customers affordable short-run printing or prototypes. Digitally printing your overlay provides endless design flexibility and imagination. While color matching is not as exact as screen printing due to the lack of variety in inks.

Digital printing advantages including: design flexibility like full color images, great for very small prototyping volume, prints multiple colors CMYK at once, cost effective and fast turnaround for prototypes. It is most economic for lower quantity and multicolor parts.

Graphic Overlay Printing can be done with digital, screen-printing, or a combination of printing processes.

What shape and size can you produce?

Your graphic overlays can be produced to any shape and size you desire. We can do custom cutouts for connectors, too.

Graphic Overlay Specifications

Adhesives or Selective Adhesive

To finish your custom screen printed graphic overlays, we offer a full range of 3M and equivalent adhesives.

3M9448A, 3M467MP, 3M468MP, 3M9080, 3M9075, 3M200MP, 3M200LSE, 3M300LSE, 3MVHB, 3M Electronics 3M9448HK, TESA and Nitto Adhesive etc.

3M 467MP: Recommended for smooth or light textured surfaces. In most cases, flexible graphic overlays are finished with 3M 467MP on the backside. This is an excellent adhesive for bonding to smooth metal and high surface energy plastic surfaces.

3M 468MP: Recommended for medium textured to rough surfaces. For rougher surfaces, 3M 468MP adhesive is recommended.

3M 300LSE: Recommended for low surface energy plastics, polypropylenes. Some surfaces such as powder coated surfaces have lower surface energy, 3M 300LSE are more appropriate for low surface energy applications.

Another method is to print 3M7533 glue with screen printing.

Adhesive Free for windows and buttons.

Adhesive or selective adhesive can be added for simple application procedures.

We are able to produce quality industrial screen printed graphic overlays in a variety of shapes, sizes and printing options to meet your exact specifications.

Selective Texture

Texture or selectively textured finishes can be added to the surface of an graphic overlay. The more common choice is the velvet finish which is excellent for hiding surface scratches.

Embossing and Buttons

Embossing can be easily integrated into the manufacturing of graphic overlays to give buttons a positive feel. Embossing is a technique that creates a ‘bubble’ or a raised section of the switch to highlight button positions or give a tactile feedback to the user. Embossing the overlay surface delivers a unique look and feel to your products interface.

Light Block (Blocker)

Usually a printed color like white, black or sometimes even metallic inks are used to increase opacity. Especially needed on overlays with illuminated displays to prevent light from “bleeding” into other areas of the panel.

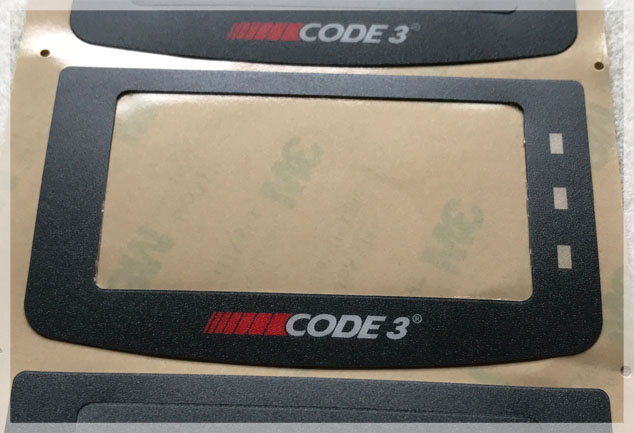

Windows, LCD Windows, LED Windows

Graphic overlays are commonly provided with clear windows for viewing LCD’s and we provide protection film to a clear window.

If your overlay will be placed over LCD, LED’S or other types of electronic displays, a clear or colored tinted window can be created. This allows the interface to have a clean look while still providing all of the required functionality.

Window tints with translucent colors can be used to indicate specific functions on membrane keypads.

We can print tinted windows in a range of colors like black, grey, red, green, orange, yellow etc.

Usually graphic overlays windows are adhesive-free windows.

Dead Front

Dead front overlays offer all the benefits of our standard graphic overlays as well as offering additional panels that are only visible through reverse lighting. Dead front effects can be printed with semi transparent inks so LED’s can be “hidden” unless they are lit up.

Custom Graphic Overlay Manufacturing

We are Custom Graphic Overlays Manufacturer, Cheap Custom Lexan Graphic Overlay, Polyester Graphic Overlays Printing, Digital Printed Graphic Overlays and Quick Turn Prototype from China.

Rapid prototyping for urgent projects or testing. Our Graphic Overlays can be manufactured to your exact specifications.

Get a free quote

For more information about custom graphic overlays, contact us now.